From design to production

We develop custom designs for our customers in electronics, industrial automation and domotics

Circuit board design

Lomar production environments

Circuit board assembly (pick and place) and functional testing

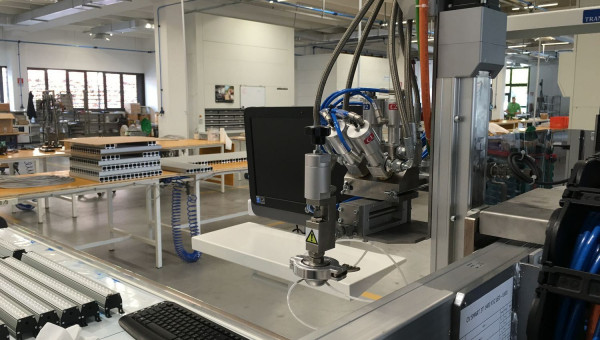

Pick and place circuit board assembly

Testing using the Flying Probe Test System

Selective soldering and wave soldering

Selective soldering process

Wave soldering process

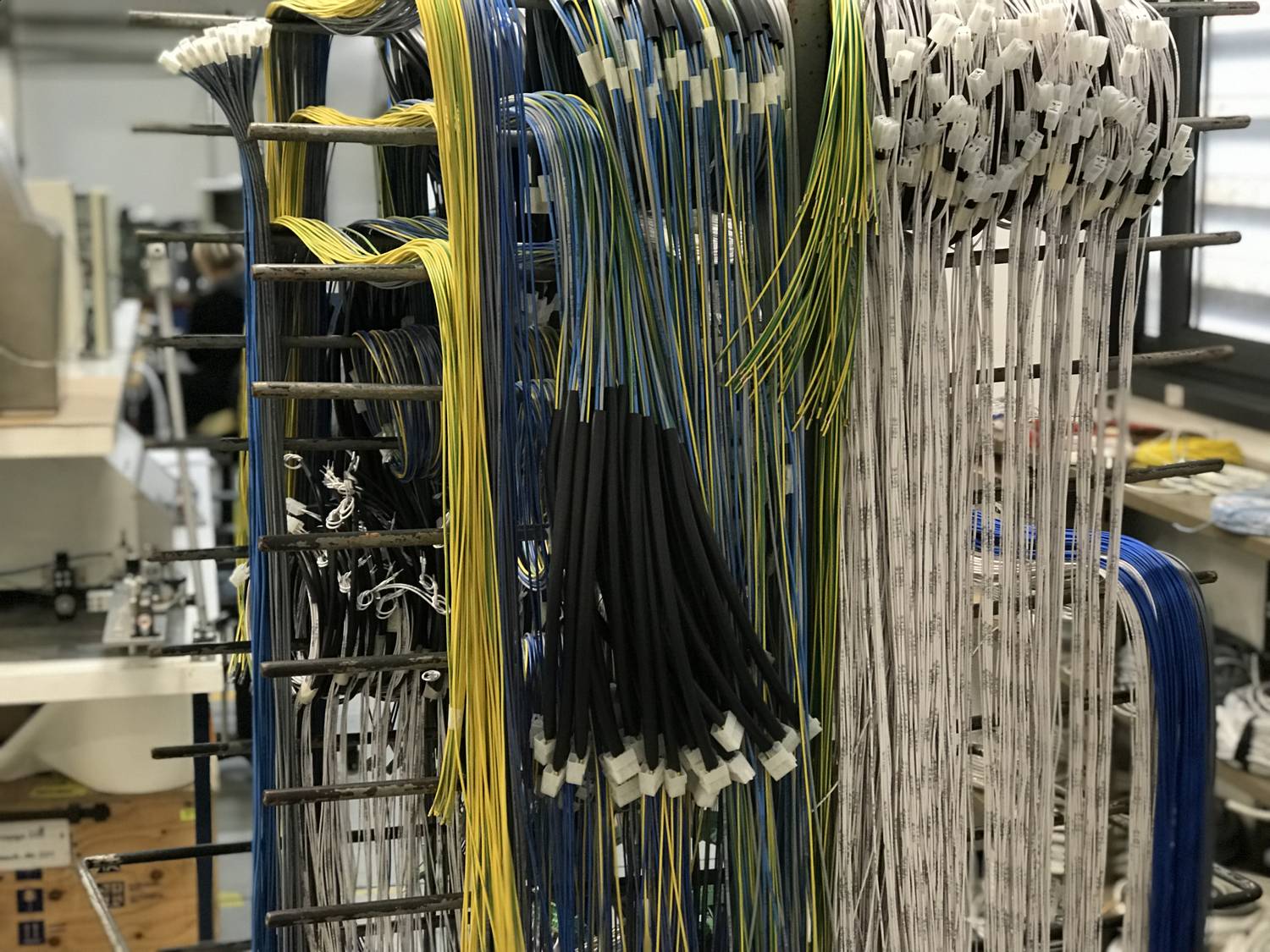

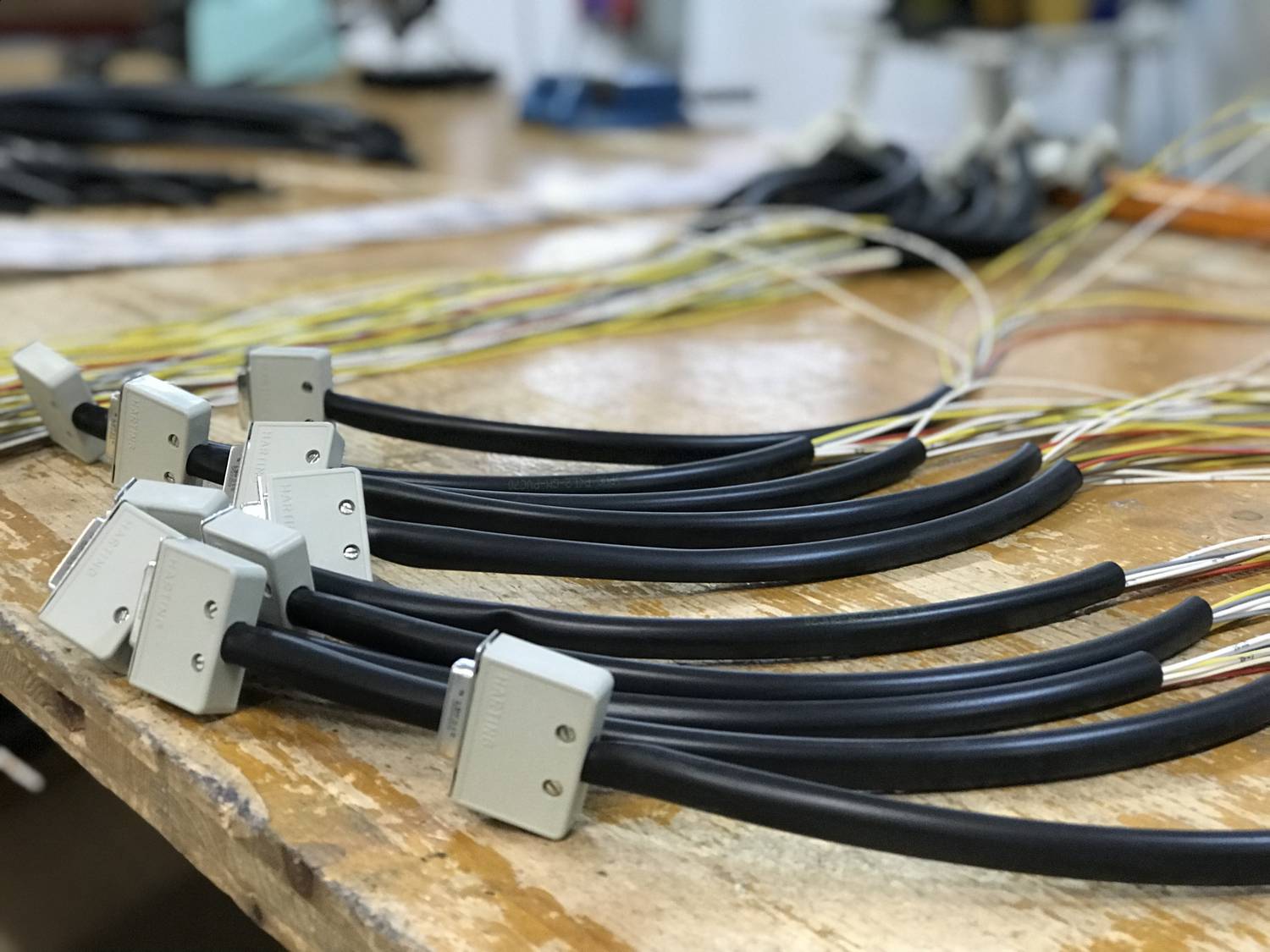

Wiring and cable marking

Machine for cutting to size, exfoliation and marking wires

Every single cable is produced at Lomar

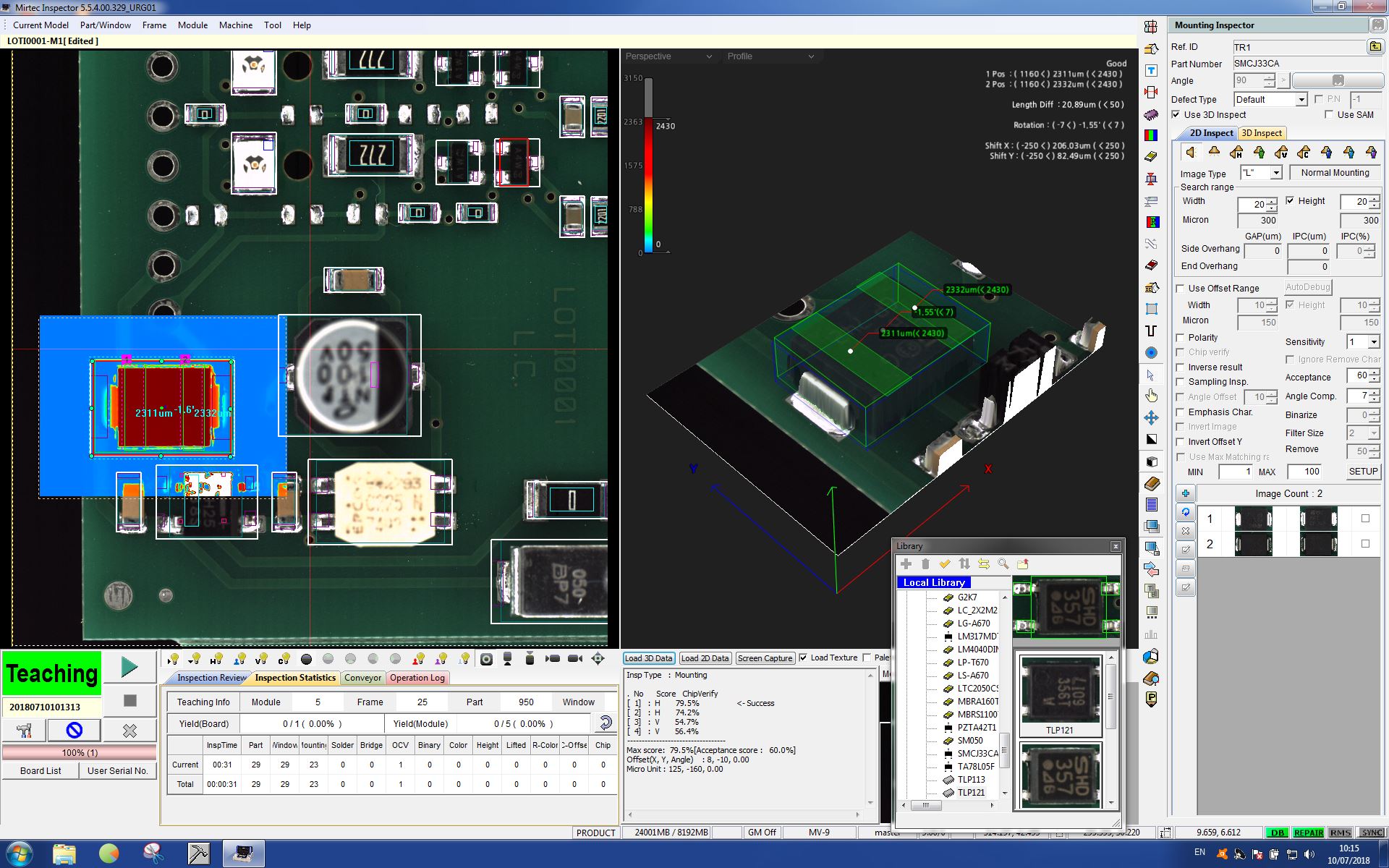

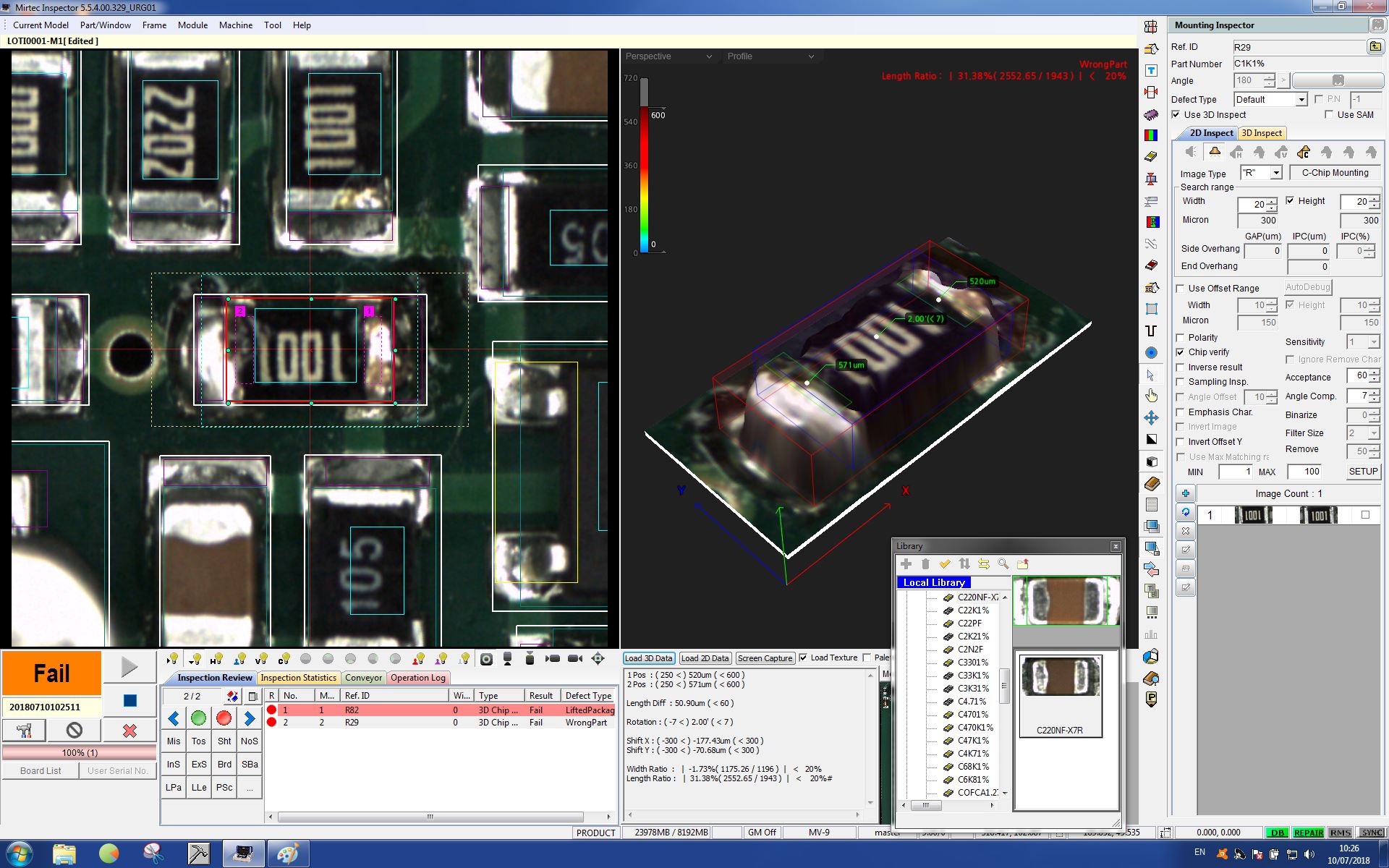

Optical circuit board inspection

3D AUTOMATED OPTICAL INSPECTION

For the quality control of our circuit boards, we rely on an advanced and modern optical inspection system that uses 5 high-precision digital cameras with resolution of more than 10 microns per pixelto check the circuit boards quickly and accurately, providing high-resolution images in both 2D and 3D of every single assembled component.

Quality and Certification

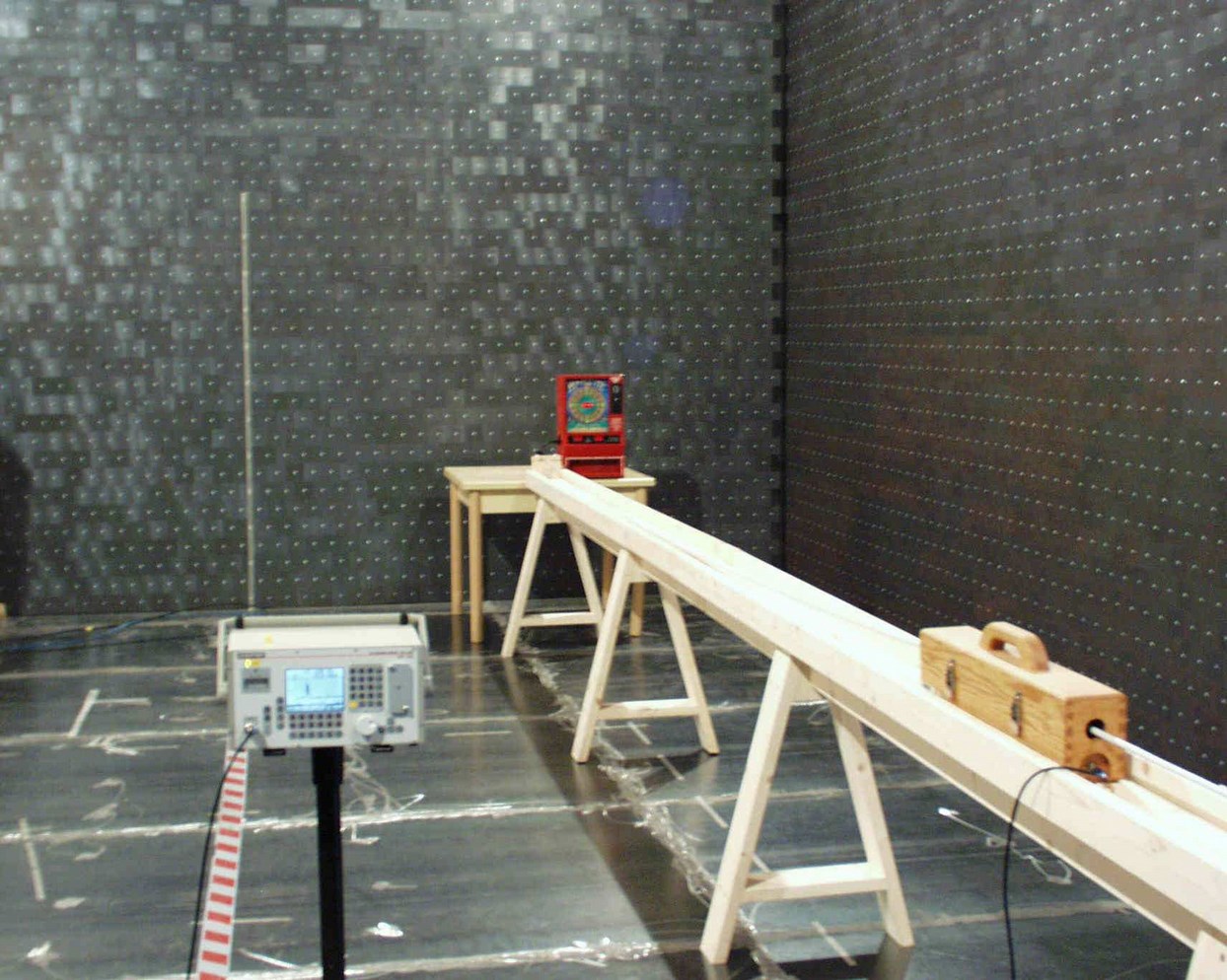

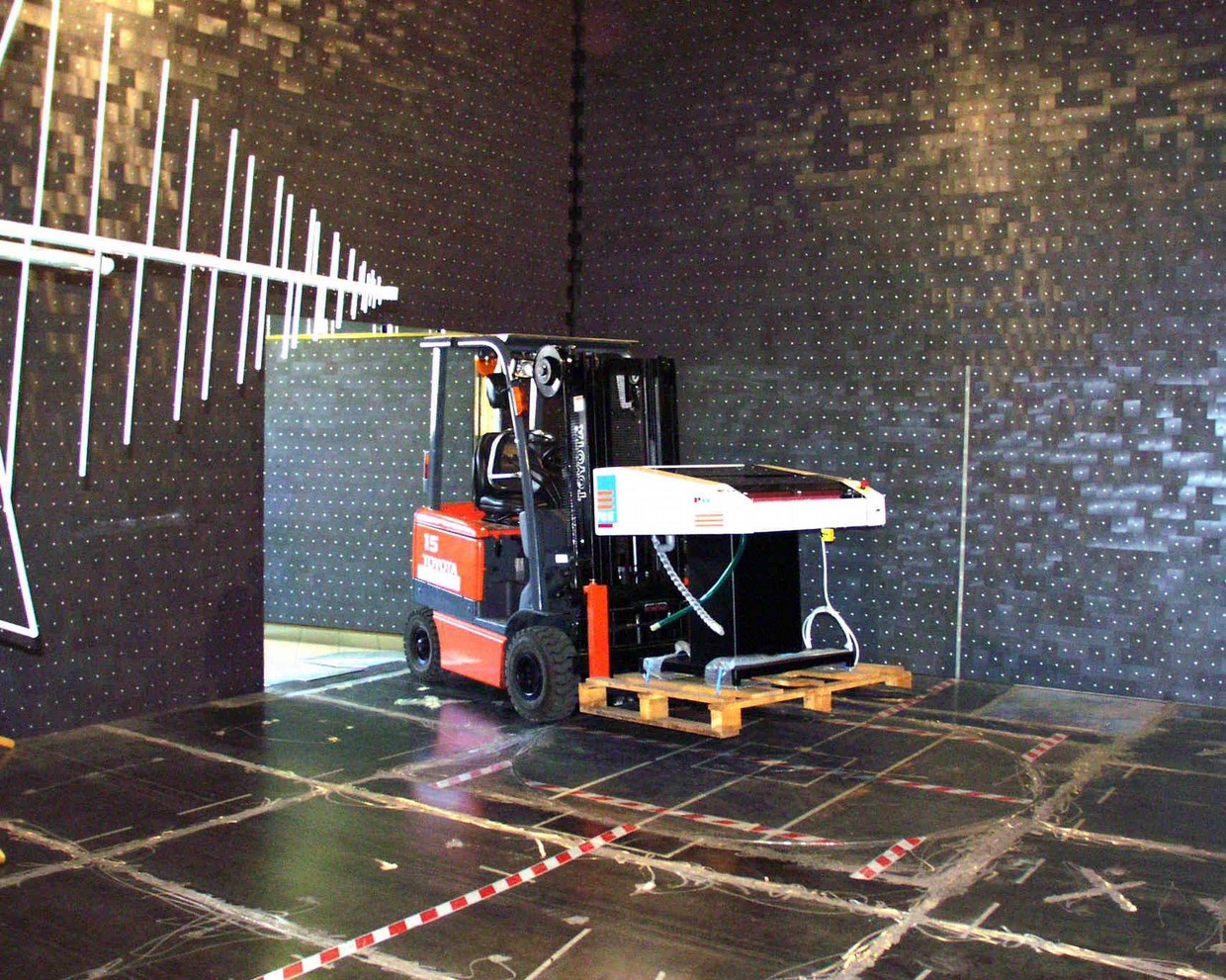

LOMAR LABORATORIES

A perfectly equipped laboratory with semi-anechoic chamber of dimensions 9.7x6.2x6h metres (one of the largest in Italy) enables us to perform rapid and accurate radiated field immunity tests, with frequency ranges from 26MHz to 18GHz, for certifying our products' conformity to the regulations in force

ANECHOIC CHAMBER

Lomar has its own semi-anechoic chamber, among the largest found in Italy, which, thanks to its steel shielding, guarantees the attenuation of outside electromagnetic interference by at least 100dB for the full range of frequencies from 10kHz to 18GHz.

Discover our Solutions