We design and produce LED lights

Certified and guaranteed for up to 5 years

The lights produced by Lomar are designed and created to get the best out of the efficiency and lighting quality of LED technology.

All the electronic components are produced and assembled by Lomar and tested individually to guarantee quality and useful life, whilst the body of the lights, also made by Lomar, are produced in aluminium for good dissipation of the heat produced by the light and to guarantee optimal operating temperature and good durability.

LED LIGHT DESIGN

Our design department and our production department, equipped with the very latest high-tech support, offer optimal engineering solutions suitable for all system variations and referring to real operating conditions.

From the initial design stage with video CAD, we create a prototype that, after rigorous laboratory testing, will become our LED light.

Every stage is performed at Lomar: from research and development to assembling the electronic components produced in our electronics department with the structure (body/holder) supplied by our machining department.

RESIN COATING

We use resin coating to protect our lights by isolating the electronic components from humidity and water.

We offer various different finishes, depending on the environment of use: clear, frosted (anti-glare) and with different levels of hardness (ground installation).

Therefore, our LED products can be used in any environment, even where there is water or dust, with guaranteed high resistance to water and pressure (IP69K).

LED STRIP EXTRUSION

Lomar's LED strips are produced entirely at our production sites and boast on-board current regulators to ensure consistent brightness for the full length of the strip, whilst maintaining a high degree of flexibility.

Available in various colours and light intensity, both white and multicolour, they can be produced bare or coated in PVC by means of our exclusive extrusion system, which also gives them IP65 protection.

WATER RESISTANCE

Our range of lights with IP69K protection have very high water resistance and easily withstand highpressure(up to 100 BAR) and high temperature water jets (up to 100°).

In extreme environments (farming, industrial plants, etc.), these lights really make the difference thanks to their exclusive connection system (FCL).

FCL ELECTRICAL CONNECTION

FCL stands for Fast Connect LED, i.e our system of rapid cables which require just a few steps to obtain a secure and stable connection. The system is made up of a power supply and control cable with an insulating neoprene sheath and lights fitted with insulation piercing connectors that require just a few second for connection.

The LED lights are connected quickly and safely, free from the risks of naked wires and with cables that ensure insulation and watertightness over time.

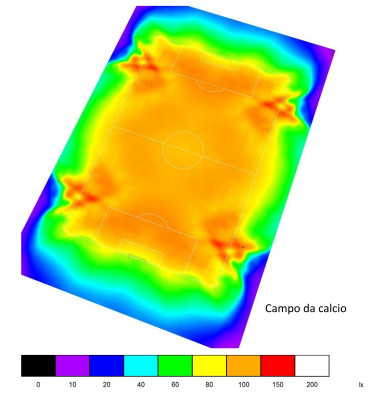

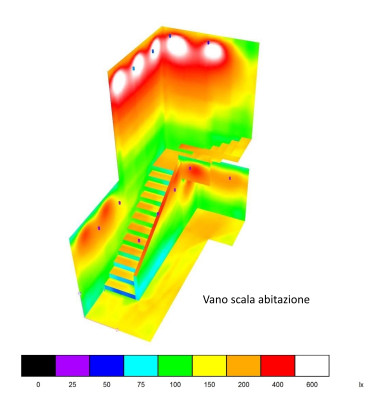

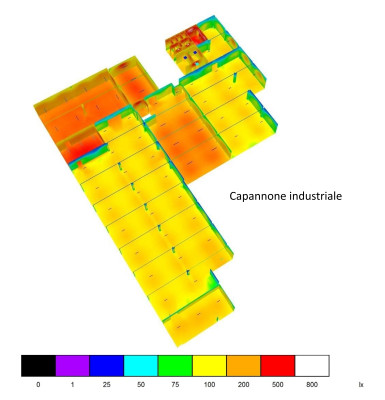

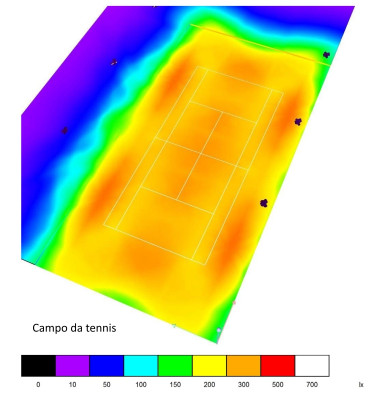

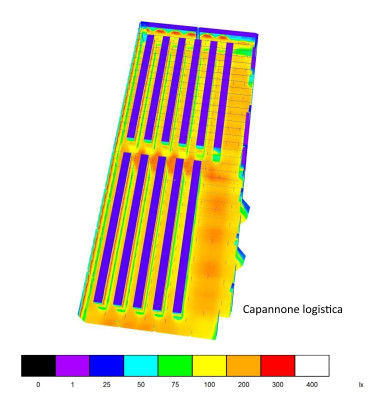

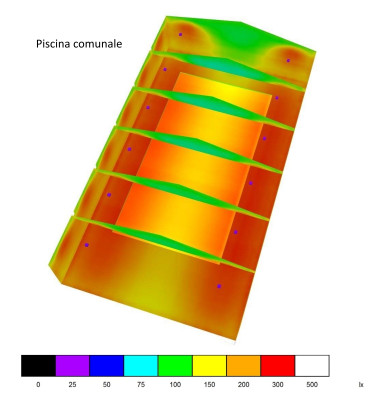

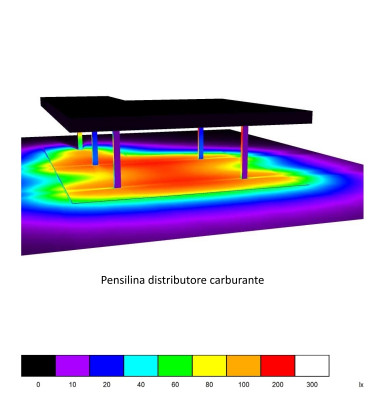

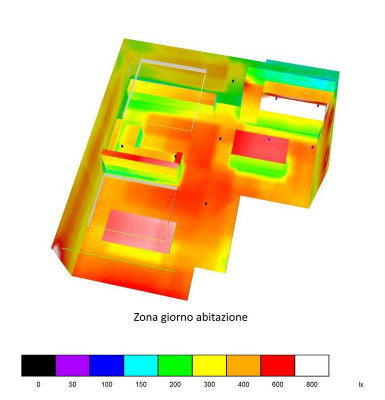

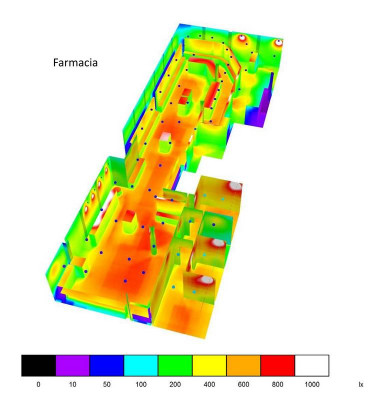

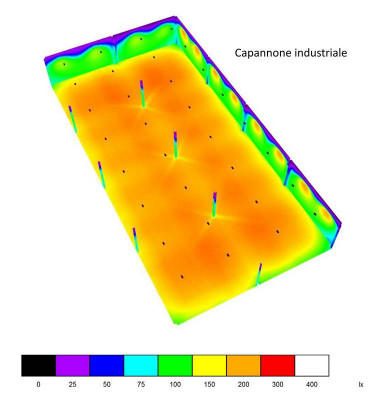

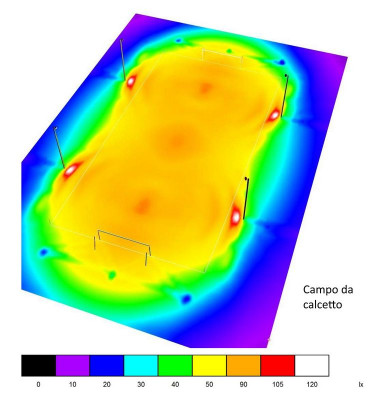

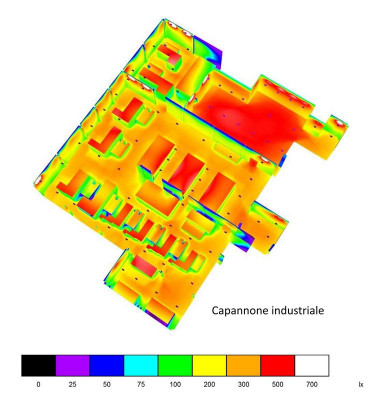

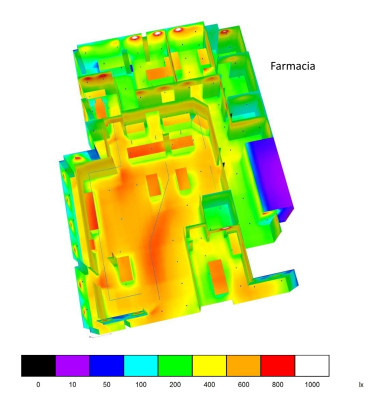

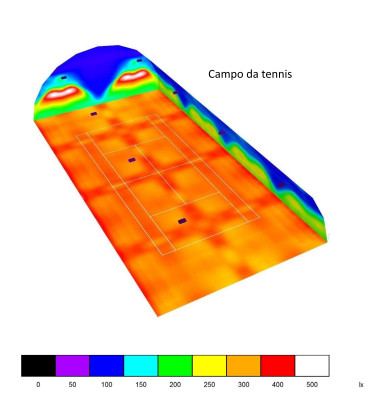

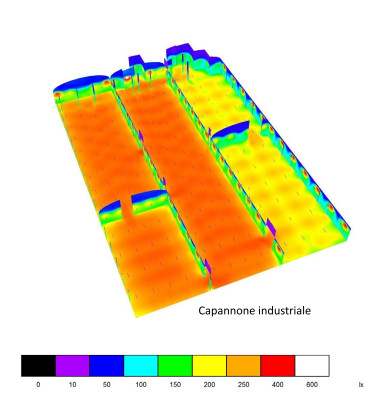

LIGHT SIMULATION

Lomar creates customized and guaranteed lighting solutions thanks to our advanced light simulation systems.

Our design department can develop lighting projects tailored to fulfil the requirements of any type of customer application, be it industrial, residential or for animal husbandry.

We use technical lighting calculations to simulate the light that will be emitted by our lights in the requested environment, whether it be indoor spaces or outdoor areas, to guarantee that the Lomar installations completely satisfy the demands of our customers and that the levels of brightness produced comply with the relevant regulations in force.

LED lighting for any environment

Browse our online product catalogue to find the ideal solution for your lighting needs